Fresh fish is not really fresh, even straight from the boat. The way they are caught and killed is not only inhumane but detrimental to the resulting meat. There is a far superior alternative, but it is time consuming and manual – but Shinkei Systems has found a way to automate it, even on the deck of a moving boat and landed $1.3m to market its machine.

It’s unpleasant to think about, but fishing for fish doesn’t really take into account the comfort of the fish. How could this work at the scale of fishing boats? What usually happens is the fish are tossed out of the net, roughly sorted and then tossed onto ice to thrash about and finally suffocate minutes or hours later. Not great!

This is not only cruel, but causes the fish body to break down faster due to stress, bacteria in wounds, and blood and lactic acid in the muscles.

Of course, anyone who catches fish one by one knows to either keep them alive in the water or kill them immediately to get the best taste. Usually this involves stunning him with a blow to the head, then decapitating and gutting him. Still not pretty, but it’s better than the alternative.

Yet there is an even better method, a traditional Japanese method called ike-jime. Doing it this way is not only the most humane, but also preserves the meat so well that it can last days or weeks longer than smothered fish and also tastes better. The problem is that it is a kind of art.

Ike-jime is to pierce the brain with a sharp tip to send the fish to fish heaven, then quickly exsanguine it, then destroy the spinal cord. Horrible, yes, but all of these things prevent stress, suffering, and the spread of bacteria and destructive substances in the body. But it has to be done precisely and within a few minutes of catching the fish, so it doesn’t really scale.

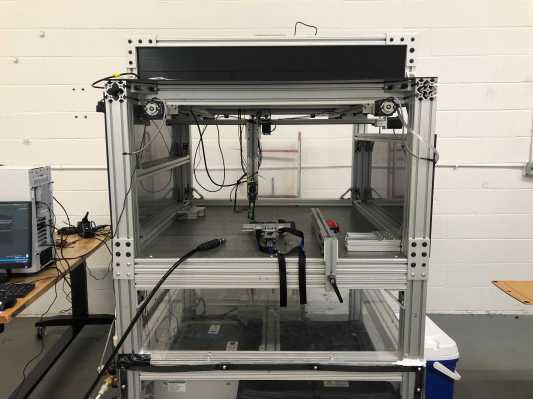

That is, unless you automate it, which Shinkei Systems did. The team, led by founder Saif Khawaja, created a mechanical way to perform ike-jime on freshly caught fish, one every 10 to 15 seconds.

A Shinkei machine on a fishing boat, left, and founder Saif Khawaja, right. Picture credits: Shinkei systems

The machine, the size of a large refrigerator, includes a hopper for incoming fish, an operational area and an outlet where it can go into an ice bath. A computer vision system identifies the species and shape of the fish it is holding, locates the brain and other important parts, and performs the ike-jime movements, dispatching the fish quickly and reliably.

“The robotics works with surgical-level precision – our vision for this is that it’s completely hands-free, without an operator,” Khawaja said, noting that it’s also robust against natural boat pitch and roll. “But it’s not just edge detection; we use machine learning in our backend. Even in the same species, even with the same outline, the brain may be in a different place. The advantage of our technology is that we adapt to all fish.

Nor was all this done in an isolated Silicon Valley garage. “We have already deployed our first versions in pilots; When I started this project, I was taking midnight Greyhounds to get to the docks at 3 a.m. when they come out, because that’s their only way to talk to them. We work with anglers in Maine, New Hampshire, and Cape Cod, and have partnered with distributors at top restaurants in Manhattan.

It’s not just for the fish that Shinkei and his partners go through all of this. Kitchens pay a premium for fish processed through ike-jime because it tastes better and lasts longer. The question for Shinkei was whether their machine-processed fish compared to handmade.

Fish processed via ike-jime, left, has less blood leaking into the flesh and is said to taste much better and last longer. Image credits: Shinkei systems

“Probably the most exciting thing that happened, also the simplest, was that we handed over our fish to a sous-chef at a Michelin-starred restaurant, one of the best in the world,” Khawaja said. “We gave him three cans of fish: one asphyxiated, one transformed by hand, the third was us. The muffled one was obvious, but he couldn’t tell the difference between the other two.

Sushi chefs are more likely to know the technique, but ike-jime is starting to gain traction outside of its current slot and Shinkei aims to accelerate that. By simplifying the loading of a machine, they can allow more fishing boats and distributors to participate, earn more money and also respect the fish.

Shinkei raised $1.3 million in a pre-seed round filed in January and is now looking to invest more, after conducting initial testing and revising the design. “What we’re doing with this augmentation is improving R&D and improving the throughput of the device,” which runs slower than expert humans but has plenty of room for improvement. “We should be ready to go into production in the next few months. Now that we are in the sales process, we are also meeting more large-scale distributors and state-owned companies. We just want to put the machine in people’s hands.